Dear Customer,

As always thank you for your custom and welcome to our first newsletter of the year. As you know it is never our intention to needlessly add to your inbox, but only to send newsletters to you when we have important and innovative changes to communicate. In this issue we would like to update you on a number of new introductions available on the website and in our production facility to further improve the quality of products and services available to you.

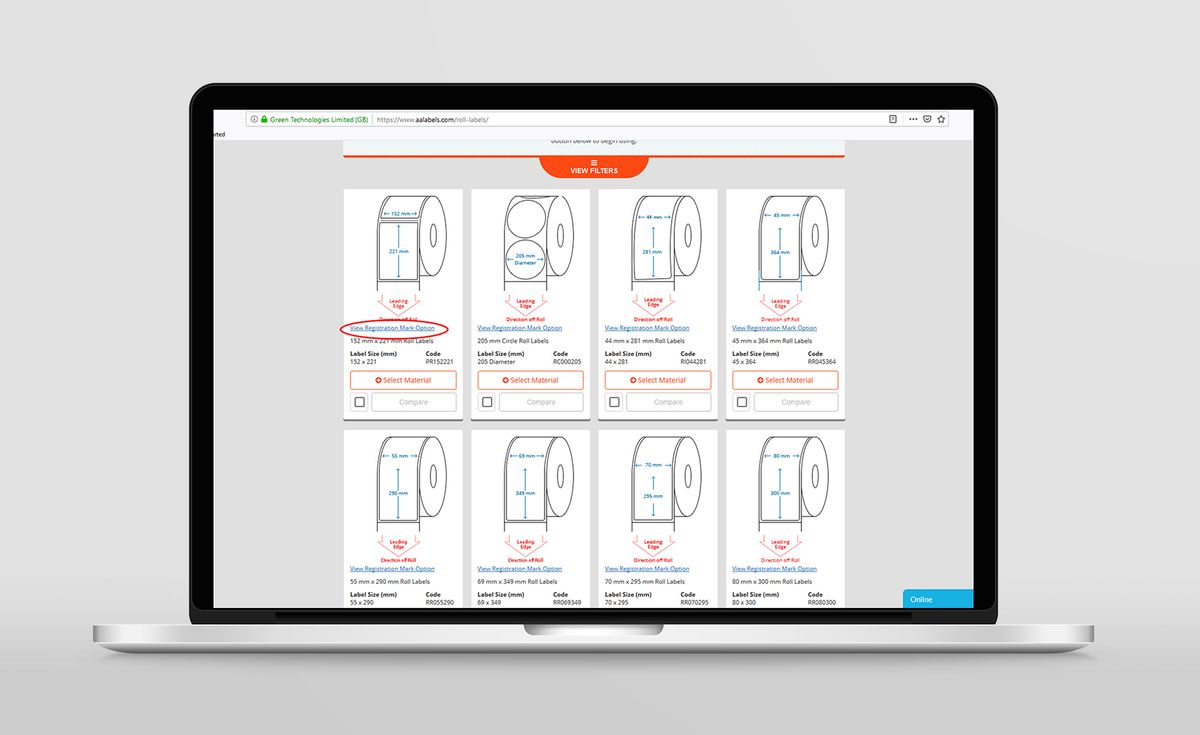

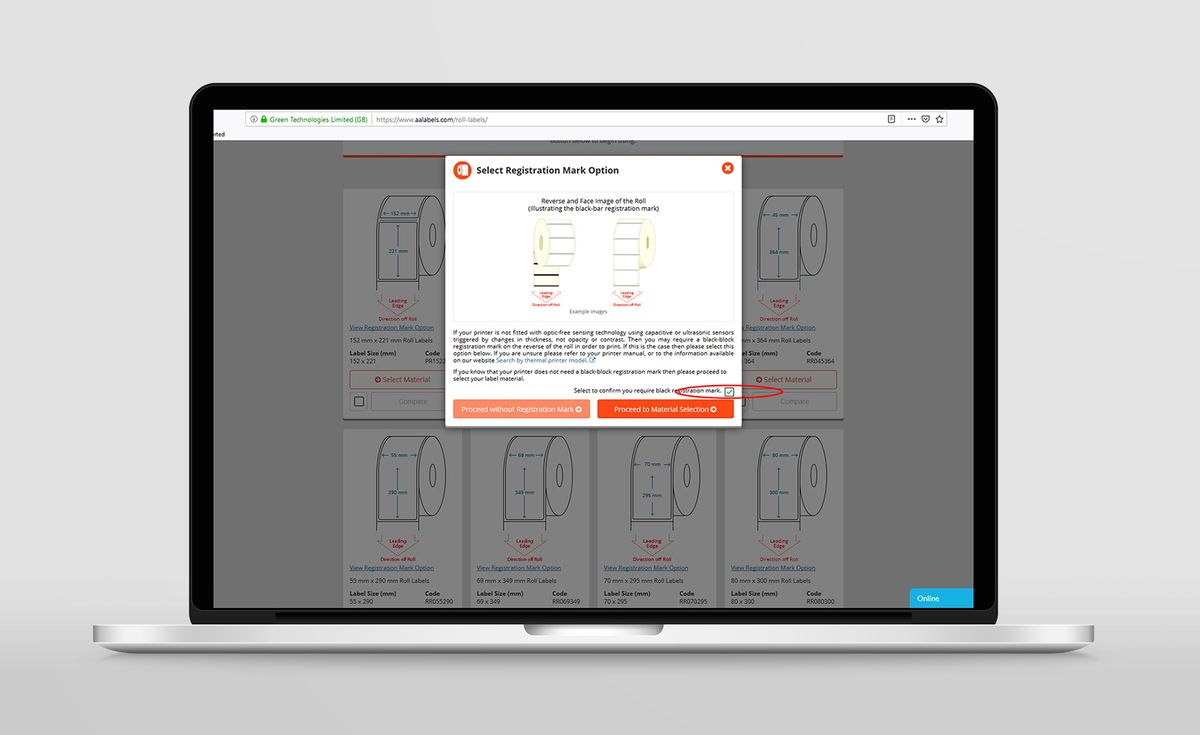

If your roll label printer requires the labels to have a black registration mark on the reverse of the liner in order for the printer to identify the start of the label, this option is now available for selection when ordering from our website.

If your roll label printer requires the labels to have a black registration mark on the reverse of the liner in order for the printer to identify the start of the label, this option is now available for selection when ordering from our website.

If your roll label printer requires the labels to have a black registration mark on the reverse of the liner in order for the printer to identify the start of the label, this option is now available for selection when ordering from our website.

In support of this recently introduced black-block registration mark option for roll label printers with optical sensors, we have also produced an informative guidance article in the form of a blog on our website, providing information on roll label printers and sensor types and the critical elements to consider when ordering plain labels for Inkjet and Thermal roll label printers. Read More

Our popular range of standard sized labels on A4 sheets has been enhanced by the addition of a print option on the website. Now from as little as 250 sheets in an easy to use and store dispenser box up to as many sheets as you require can be pre-printed with your brand and business ID leaving only the variable data to be printed by you in monochrome. Not only does this save time and money on coloured ink and toner cartridges through reduced usage, but the quality of commercial print enhances the standard of presentation.

We have added a matt white Polyethylene label with a pink reverse side to increase the label opacity and therefore also function as a durable block-out or cover-up label with a permanent and strong water based acrylic adhesive providing good adhesion to a variety of surfaces, with good material resistance to chemicals, oils, water and UV light.

This is a good general-purpose label material designed for, although not limited to commercial and industrial use.

The short product code for this material is PEOP and if you have previously ordered Polyethylene labels on rolls (Product Code: PETP) you may wish to order a sample to ensure that you are happy with any slight changes in appearance.

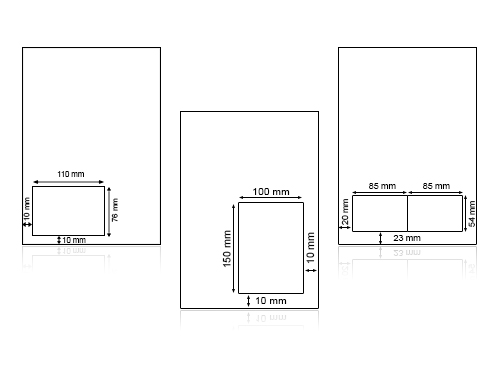

As a direct result of our Integrated Labels representing such good value for money, we have seen a huge increase in the numbers of customers requesting quotes for different individual label layouts. If you have a label format in mind, but never thought that it could be affordable on the smaller quantities required please contact our customer care team to discuss your requirements and receive a quotation, we think that you will be pleasantly surprised!

In support of this recently introduced print option for Integrated Labels, we have produced a short but informative guide regarding the benefits and options available for the use of this versatile and adaptable label format. Which can be found under the “Labels” heading on our website Blog page. Read More

We have added over 40 new sizes to our range of label shape options in circular, rectangular and square formats and will continue to add popular sizes popular sizes that customers ask for. If you have a specific label shape and size requirement please let us know as we may add it to our standard range.

Despite only having installed our latest sheet converting machine in the summer of last year (2018) In order to respond to a continuing demand for high quality label production from our customers, we have installed yet another new, fully modular converting line from the ABG 330 Series, (Model: Omega 350) to further increase our production quality and capacity for labels on sheet formats. While also enabling the continued extension of the range of sheet formats, label shapes and sizes available with our innovative “Dry Edge” sheets, providing faster, problem free printing for customers using plain labels.

This now takes us to a total of 5 converting lines for sheeted label production:

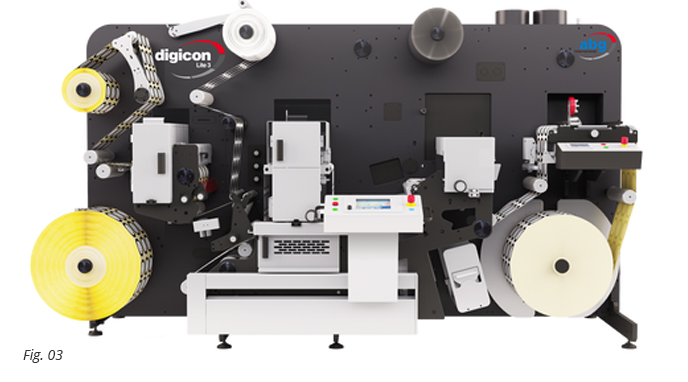

In addition to which in the Autumn of last year we also added another roll label convertor to our production unit late last year which was the ABG Digicon Light S3 (Fig. 03)

This now provides 3 dedicated roll label converting lines:

While in our print room for the production of printed labels we have 2 commercial reel-to-reel presses, one inkjet and the other electrostatic ink technology, plus two flat sheet printers.

In terms of production staff operating the equipment we are now up to a team of 12 people within the factory and warehouse. It is this continuous investment in people and technology that assists with Improving and maintaining quality control and capacity to respond to the continuing growth in customer demand for both printed and plain labels, in sheet and roll formats, throughout Europe.

We take pride in our service standards for all customer enquiries and orders. Our reputation for service is built on quality, a comprehensive product range and fast order fulfilment times, along with the combined experience and knowledge of our customer care team. If you need assistance or help regarding the most suitable choice of label, packaging, or promotional item for your application, please contact our customer care team, via the live-chat facility on the page, our website contact form, telephone, or email and they will be happy to discuss your requirements.